MENU

What is 5S?

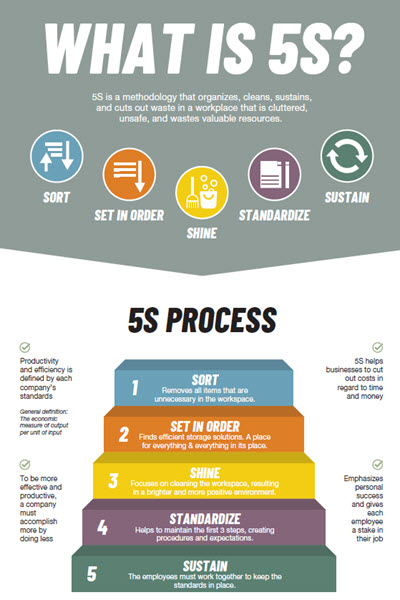

As an industry leader, you are always looking for ways to give your company over the competition. One way to accomplish this is to find ways to do more with less. The 5S system is a lean manufacturing tool that reduces waste and improves workplace efficiency.

5S Definition

What is 5S? The 5S system is a step-by-step way to transform a workplace from one of disorder and clutter to an organized and productive one. 5S helps you improve worker safety, productivity, quality and efficiency. And, it accomplishes this by removing what’s called the Eight Wastes.

5S Origin

5S was developed in Japan as part of the Toyota Production System manufacturing method. On a visit to the U.S., three representatives from Toyota observed the processes of two major companies, Ford Motor Company and Piggly Wiggly. The enormity of the operations impressed them. They were surprised, however, at the amount of waste that was occurring at Ford, and noticed wasted steps that had been leading to overproduction, layoffs and rehires.

At Piggly Wiggly, they were very impressed with their inventory management system. They noticed that the company ordered only what was needed (Just-in-Time Inventory) rather than storing excess items.

After gathering information from the two companies and returning home, they began to analyze the waste that existed in their own plants. They viewed their labor costs, inventory management and lost production hours. They examined their profit margins and total production costs. Then, they created a system that addressed waste through the use of repeatable and replicable processes.

These were the now-famous origins of a simple five-step process that has helped thousands of companies succeed. The 5S solution has been used all over the world and continues to find new advocates each year.

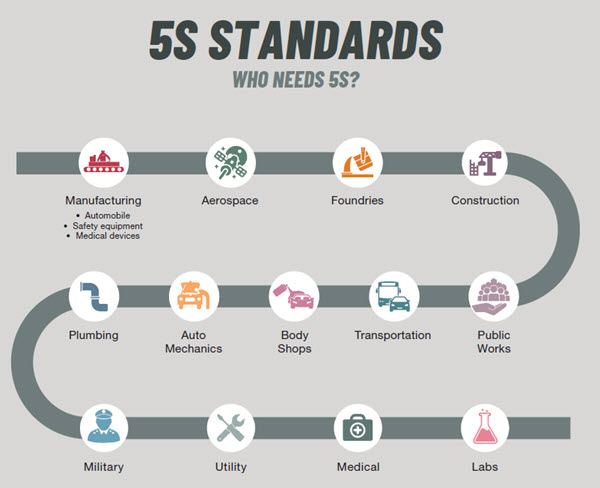

Any industry can be a 5S workplace. These are just a few examples of work environments where 5S is making a positive difference every day:

Computer Manufacturing - Hewlett-Packard uses the 5S pillar of seiton to organize and stack parts in its storage areas for easy access similar to the way products are stacked on grocery store shelves. This allows the company to streamline daily processes by arranging the workspace in a way that eliminates unnecessary motion.

Aerospace Industry - Boeing uses a type of 5S system called the Lean Production System. This system adds an extra focus on safety to the traditional five pillars. This version of the methodology allows Boeing to simplify and secure its offices and warehouses while maximizing efficiency.

Automotive Industry - An increasing number of Harley-Davidson factories are using lean manufacturing techniques to streamline operations. The move to 5S has bolstered a struggling operation by saving money and increasing safety.

5S Process: Step-by-Step

The 5S meaning is a series of steps that represent each of the five S-words in the process:

Step One: Sort (Seiri)

This first step removes all unnecessary items from the workplace with red tags. The reviewer will assess the workplace and attach tags to items that aren’t needed. This part of the process eliminates clutter and frees up space.

Red Tags are essential for this step.

Step Two: Set in Order (Seiton)

After red tagging certain items, the next step is to find efficient storage solutions, like labeled holders and tool organizers—a place for everything and everything in its place. The Set in Order phase ensures all team members know exactly where and how specific items are stored.

Tool Organizer Kits and Label Holders & Tags are helpful tools for this step.

Questions To Ask During the 5S Set In Order Phase:

- What is needed to get the job done?

- Where should items be located?

- How many of the items do I need?

Once a space is organized, it's time for step three.

Step Three: Shine (Seiso)

The Shine phase focuses on cleaning the workplace. This results in a more positive and brighter workplace. Sparkling spaces make defects more obvious, and areas can receive service and maintenance as soon as they need it.

Employees are also motivated to be more productive in cleaner workspaces. Who wants to work in a dirty area? Workplace cleanliness is linked to increased morale and job satisfaction.

By developing regular cleaning habits, you can be sure that every work area is ready for use. Color-coded cleaning tools and equipment help keep them where they belong. This cuts down on time searching or preparing equipment for use. The cleaning phase also makes non-conformance to 5S standards much more visible.

The next step is to begin to systematize your setup so that it becomes a long-term solution to productivity problems in your workplace.

Step Four: Standardize (Seiketsu)

By implementing this step, you’re able to maintain the first three steps more easily over time. Now you can communicate the procedures, responsibilities and expectations to your team. By standardizing procedures, you ensure that the desired procedure changes remain in place. What’s more, you can make sure the ineffective conditions of the past don’t resurface.

Tool Shadow Boards and Color-Coded Cleaning Tools help standardize operations.

Finally, let's look at what is perhaps the most important step, sustaining.

Step Five: Sustain (Shitsuke)

Without proper support, the Sustain phase can be difficult. Workspaces have been cleared of clutter. They are cleaned and procedures are set in place. The company must now work together to keep these changes in place. It must become part of the company culture to be effective.

Routine inspections are necessary. Inspections make sure the company doesn’t fall into old habits and routines. There’s another important aspect of 5S. It’s important to remain flexible and adopt new procedures as your company’s needs change.

5S Methodology

The 5S methodology seeks to eliminate eight common workplace wastes.

Common Wastes in the Workplace:

1. Defects: Most people only think of the scrap cost associated with a defect. The costs of problem-solving, materials, labor hours, paperwork and decreased customer retention are much higher than the scrapped item.

2. Inventory Waste: This is the number of raw materials, work in progress or finished goods that a company is holding. Each piece of inventory carries a cost and is likely gathering interest. There are additional costs from overproduction, storage, transportation costs, damage, loss and paperwork.

3. Movement and Energy Waste: Just because an employee is moving doesn’t mean they’re working. Think of all the wasteful steps in a current process in your facility. Are employees forced to take unnecessary steps to perform their job functions? Employees that exert more energy on non-value-added processes like lifting, retrieving or searching produce less. They’re also at higher risk of injuries.

4. Processes with No Value-Add: Are employees spending time and energy doing work that isn’t part of their job? For example, are they sanding or polishing areas that aren’t visible in their final form? Not only does that cost time and labor, but there’s also increased material and equipment usage. The more a company uses the equipment, the more costs are associated with maintenance, service, repair and replacement.

5. Overproduction: Overproduction leads to unreliable processes, unbalanced work cells and inaccurate predictions of future orders. Overproduction is also responsible for holding up capital in raw materials, stocked items and finished goods. As a rule of thumb, companies should avoid overproduction by balancing supply with demand.

6. High Transportation Costs: By limiting transportation distances, companies can minimize the costs of overproduction, transport, storage, damage, loss and material handling fees.

7. Waiting and/or Wasted Time: How often do you notice employees standing around? Are they waiting for a previous step in the process to be completed? Are they waiting for parts, supplies or products to arrive? Are they waiting for clear instructions on their next step? The cost of waiting is huge and you can never recover those costs.

8. Non-Utilized Talents: Under-utilizing the talents of employees is a huge waste of energy and innovation in the workplace. Ask yourself, what standard systems does our workplace use to ensure we are maximizing our people's talent?

By removing waste and developing standardized processes, you can achieve a clean and organized workplace.

5S assesses everything in the current workplace. Then, it removes what’s unnecessary and performs ongoing housekeeping tasks. Finally, 5S provides storage solutions that allow workers to be more productive and less stressed.

The key to productivity and success is to enable employees to have a personal stake in their job. To do that, employees must have ownership over their positions. Through clear direction, improved habits and standardized practices, employees can become more confident in their abilities. Confidence inspires problem-solving and attention to detail, which are key ingredients for highly productive work environments.

5S Standards Found in the Workplace

The 5S system has gained prominence in the workplace because of its effectiveness as a tool for increasing efficiency. Businesses can reap the benefits of the system by becoming proactive in their efforts to reduce waiting time, wasteful movement and cut unnecessary steps from processes.

Where It Started

Hiroyuki Hirano developed the 5S system in post-war Japan. Toyota incorporated the 5S principles into its Toyota Production System manufacturing framework. As Toyota gained international acclaim for its production processes, the 5S system spread to other large manufacturing operations, such as Boeing, Hewlett-Packard, Nike, Harley-Davidson, Caterpillar and Ford.

5S Examples Today

These are a few of the many examples of 5S practices in the modern business world:

Medical Industry - Hospitals and medical practices use 5S to ensure that medicine and medical equipment are properly labeled, promote organization and improve patient safety. The system also promotes optimized and clutter-free environments that make it easier for employees to do their jobs and increase operational efficiency.

Labels are used throughout medical facilities to ensure smooth operations.

Hospitality - The hospitality industry is a natural fit for the 5S system because the principles of order, organization, consistency and cleanliness are all attributes customers look for in top hospitality businesses. Incorporating the 5S system maximizes resource use, increases customer satisfaction and improves operational efficiency.

Education - The quality of the learning environment plays a big role in how successful students are in the classroom. Educational institutions implement 5S quality principles by removing unnecessary items, such as extra tables, cabinets, seats and materials from classrooms and utilizing the remaining fixtures and furniture in a way that maximizes the available space.

Visual Management tools are found in many industries to help reinforce and improve communication.

5S Lean Manufacturing: What It Is

5S lean manufacturing is a method for organizing workplaces in a way that produces a safe, clean and well-structured work environment. The goal of 5S lean manufacturing is to make it easier for employees to do their jobs effectively and efficiently, resulting in a reduction in downtime and risk. It is often implemented in manufacturing facilities through the use of routine tasks and visual cues.

5S Benefits

5S is most commonly used in the manufacturing industry; however, it can be beneficial in almost any industry in a variety of ways:

Improved Accuracy

5S methods ensure that the right tools and materials for the job are always at hand. This reduces inaccuracies that may be introduced by employees using the wrong tool or part for a job. Additionally, 5S systems keep machinery operating in peak condition and keep employees motivated to pay attention to details and catch errors before products go out the door.

Increased Efficiency

The 5S methodology's emphasis on reducing waste leads to a natural increase in efficiency. Companies that practice 5S methods only acquire the necessary materials, tools and equipment for the work to be done. This means employees spend less time setting up and sorting through these items. Additionally, companies use these methods to evaluate and optimize existing processes so that workers can get more done in less time.

Stronger Company Foundation

5S achieves strong worker commitment by emphasizing worker participation and encouraging workers to provide input into the overall design of the workplace. Workers who are invested in their workplace have more commitment to the quality of their work and have fewer issues with absenteeism.

Greater Economic Success

When employees can produce more with less, make fewer errors and practice better quality control, companies make more money. Additionally, 5S techniques result in improved equipment uptime, which means machines spend more time producing products and companies spend less time and labor fixing broken equipment.

Happier and Less Stressed Staff

Clean and well-organized work environments are less stressful and safer for staff. Implementing 5S strategies can significantly reduce worker injuries, particularly those caused by slips and falls or chemical spills because workplaces are better organized and less cluttered, and the need to move through the workspace is reduced. Reducing workplace injuries improves employee morale and the perception that the employer is concerned about worker safety.

Floor Tapes and Aisle Markers are used in warehouses to keep operations running smoothly.

Better Quality Products and Services Are Provided to Customers

The self-discipline employees gain by practicing the 5S standards carries over to their work product. Because employees are happier, less stressed, more productive and more committed to the quality of their work, they can provide higher quality products and services to customers.

The answer to many of the issues in your environment lies in implementing effective and sustainable 5S processes.

Closing Thoughts

5S is a cost-effective way to build a solid foundation upon which to apply other lean techniques. 5S principles touch every aspect of your business operations and set your employees up for success. Click the link below to start your 5S journey using our 5S products.

Shop 5S Products

FAQ

Who Can Benefit From 5S?

The best way to determine whether 5S is right for you is to ask yourself a few questions:

- Do we need to improve efficiency?

- Does our workplace safety need improvement?

- Do we need to make eliminating waste a priority?

- What other workplace improvement strategies are we using?

Almost any company can benefit from 5S methods; however, companies prioritizing efficiency, safety and waste reduction will see the most improvement. Additionally, while 5S is effective on its own, it can also be used as a complement to enhance many other strategies. So if you are already using a different strategy, consider whether 5S could make that strategy more effective.

How Does 5S Improve Safety?

Removing clutter from the workplace eliminates obstacles that can cause slip and fall accidents, fires and other safety hazards. 5S helps ensure employees use the right tools for the job which reduces injuries caused by misusing tools. The emphasis on keeping the workspace clean removes dust that could be a fire hazard and spills that could lead to slips and falls.

Standardizing how tasks are performed reduces the chance of errors that can lead to injuries. The effort to sustain these practices long-term ensures that workplaces continue to get safer as time passes.

How Is 5S Different From Six Sigma?

The focus of 5S is on reducing inefficiency and waste. The goal of Six Sigma is to eliminate defects by standardizing processes and identifying problem areas. There is some overlap between the two methodologies; however, they can both be used to complement and improve each other.

How Does 5S Help a Business Grow?

5S can help your business grow in a variety of ways. First, eliminating waste helps you reduce your expenses allowing you to reinvest the money you save into your company. 5S helps employees feel empowered which increases employee morale and improves employee retention. The safety improvements you will realize with 5S implementation also help your business grow.

What Can Cause 5S To Fail?

A failure to buy in from top executives is a common cause of 5S failure. 5S can not be sustained without a commitment from management and top executives. Another common cause of failure is not keeping track of the benefits. When companies fail to track cost savings and other benefits, even a successful 5S implementation may be canceled because the benefits of keeping the program are not obvious.

Finally, 5S can be difficult to implement without a clear direction. There are many different ways 5S can be used. If there are too many people trying to approach the method from too many directions it usually won't be effective. It is better to designate a core management group to manage your 5S strategies.

What Is the Best Way To Sustain 5S?

Many companies that implement 5S standards struggle to sustain the system. This is often caused by a lack of focus. Companies are excited to try new ideas at the beginning of the process, but instead of picking a strategy and sticking with it, they jump from idea to idea. A successful long-term 5S strategy requires commitment.

Make sure you get full buy-in from key stakeholders before you begin. If you encounter resistance, consider enrolling stakeholders in classes or seminars that demonstrate the benefits of 5S.

Track the metrics you hope to improve. If you can provide concrete examples of how 5S is benefiting the company, you will have an easier time keeping your team focused on maintaining the standards. Finally, celebrate your success. Whenever you achieve a win by implementing 5S techniques, make sure the whole company knows about it.

How Do I Get Started With 5S?

The first step is to assemble an implementation team. This team must be made up of members from all levels of management and front-line employees. The size of the team varies by the size of the company, but four to twelve people is a good number to aim for. The implementation team is responsible for identifying ways that the 5S standards can be used to make improvements in the workplace.

Next, you must establish a baseline. Your baseline is a measurement of how your company is doing right now. These are the metrics you will use to gauge how effective your 5S implementation is. Start with small changes. In the initial excitement of trying something new, you may be tempted to try to change everything all at once.

However, this is usually a recipe for failure. Instead, identify some small projects that will rapidly produce measurable gains. This allows you to ease into the process and build confidence that it works by demonstrating tangible benefits right away.

Once you have those initial small wins, it is important to keep the ball rolling. Maintain a list of projects to be completed and push your team to keep checking items off that list. This will both help you establish 5S long-term and transform your company culture to one of continuous improvement.

This free book will help you easily plan, manage and sustain your 5S implementation.

Request your free copy of 5S Success Mindset.