MENU

- Home

- SKU: LS-DECAL031

Notes To Lifting Capacities 1. Do Not Exceed Label, 8.5x4.5 in. XV Adhesive Dura-Vinyl

Product details

Construction

Printed

Mounting option

Self-Adhesive

SKU

LS-DECAL031

CS444265

CS444265

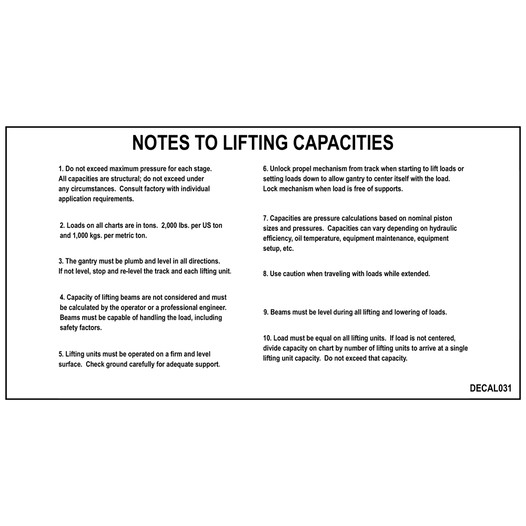

Wording

NOTES TO LIFTING CAPACITIES 1. Do not exceed maximum pressure for each stage. All capacities are structural; do not exceed under any circumstances. Consult factory with individual application requirements. 2. Loads on all charts are in tons. 2,000 lbs. per US ton and 1,000 kgs. per metric ton. 3. The gantry must be plumb and level in all directions. If not level, stop and re-level the track and each lifting unit. 4. Capacity of lifting beams are not considered and must be calculated by the operator or a professional engineer. Beams must be capable of handling the load, including safety factors. 5. Lifting units must be operated on a firm and level surface. Check ground carefully for adequate support. 6. Unlock propel mechanism from track when starting to lift loads or setting loads down to allow gantry to center itself with the load. Lock mechanism when load is free of supports. 7. Capacities are pressure calculations based on nominal piston sizes and pressures. Capacities can vary depending on hydraulic efficiency, oil temperature, equipment maintenance, equipment setup, etc. 8. Use caution when traveling with loads while extended. 9. Beams must be level during all lifting and lowering of loads. 10. Load must be equal on all lifting units. If load is not centered, divide capacity on chart by number of lifting units to arrive at a single lifting unit capacity. Do not exceed that capacity.

Description

White NOTES TO LIFTING CAPACITIES 1. Do not exceed Label for Lift Systems

Use this easy-to-read label to make your Machine Safety message clear.

- US-made label is UV, chemical, abrasion and moisture resistant for long life in a variety of environments.

- Flexible XV Adhesive Dura-Vinyl label stock has permanent adhesive with backing - just peel and stick.

- Printed with UV-stable ink and suitable for indoor or outdoor use at service temperatures from -40 to +180 F.

- These labels are made-to-order for Lift Systems, and most orders ship within 2 days from the ComplianceSigns manufacturing facility.

Click Add To Cart to order this Lift Systems label today.